Need to make resistance measurements compliant with ASTM-D257& IEC 60093/IEC 62631-3-2 Standards?

The 1865 + Megohmmeter with the 1865-11 Test Cell were designed to make dc Insulation Resistance, Volume Resistance and Surface Resistance Measurements

If your looking for more information on the megohmmeter or test cell required to make these measurements click the links above.

If your looking for more technical information including formulas on how to make surface, volume or insulation resistance measurements read below.

See the NEW ASTM D257 VIDEO on use of the 1865 Plus and 1865-11

Test Sample Resistivity Measurements

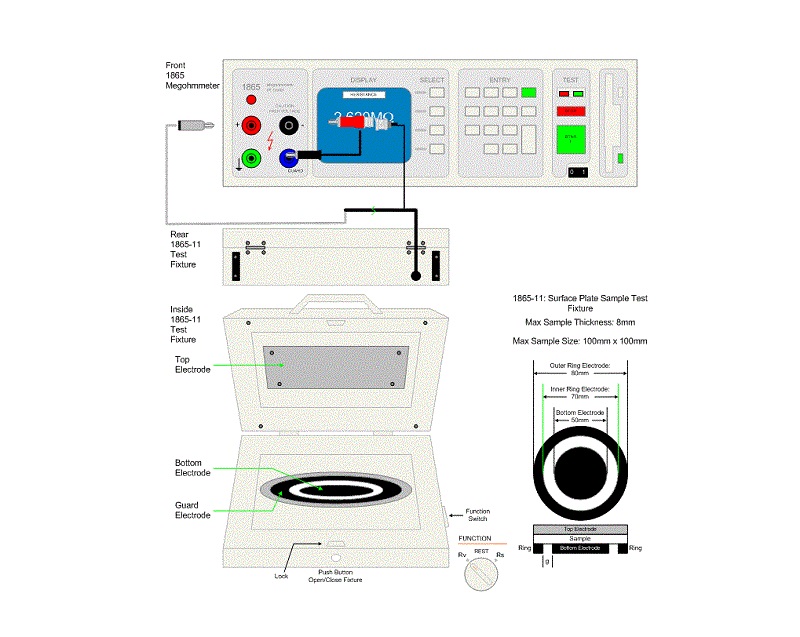

The 1865+ can be used for measuring the resistivity of test samples as described by ASTM Standard D 257, which describes in detail the techniques for both surface and volume resistivity measurements. The 1865-11 Test Cell is shown in Figure 3-1

The 1865-11 Test Cell measures resistance and with unique formulas, the resistance can be converted to surface and volume resistivity. The formulas required to convert from measured resistance to resistivity are given in the ASTM D257 Standard. For the circular or concentric electrode configuration, the resisitivity is calculated by:

Insulation resistance of materials is one of several parameters that may indicate the condition of insulation. An insulation test is to measure the resistance offered by the insulating members of a component part to an impressed direct voltage tending to produce a leakage of current through or on the surface of these members. There are times when knowledge of insulation resistance can be very important, for example; when resistance is high it may be the limiting factor in design of a high-impedance circuit, when resistance is low it can disturb the operation of circuits intended to be isolated. Insulation resistance measurements should not be considered the equivalent of a voltage breakdown test. Material with high insulation resistance could possess a mechanical fault that might fail during a voltage test and conversely material with low insulation resistance might not breakdown during a voltage test.

Factors that affect insulation resistance measurements include such things as temperature,humidity, previous conditioning, test voltage, charging current and duration of the test voltage (electrification time). It is characteristic of certain components (for example,capacitors or capacitive components or materials) for the current to fall from an instantaneous high value to a steady lower value, consequently the measured insulation resistance will increase from an appreciable time as test voltage is applied. Because of this it may take minutes to approach maximum insulation resistance readings, thus specifications usually require that readings be taken after a specified time, again electrification time. A routine test that has been widely adopted for insulation testing calls for the measurement of the apparent leakage resistance after a test voltage has been applied for 1 to 2 minutes.

AATCC 76-2000 Electrical Surface Resistivity of Fabrics covers test methods for the measurement of surface resistivity of various woven fabrics. This test method is applicable for resistivity measurements generally above 107Ω-cm or 107Ω (per square). See aatcc test method 76-2000 overview for more information.

For discussion on insulation resistance measurement methods and procedures refer to MIL-STD-202 and ASTM (American Society for Testing and Materials) Standard D257.

Here is an example of a laboratory that uses the 1865 Megohmmeter to perform testing on polymer materials to ASTM D257 and IEC 60093. Intertek polymer labs provides testing to ASTM D257 and IEC 62631-3-1

Here is an article in Evaluation Engineering that compares ASTM D257 and EOS/ESD S11.11-1993. The Difference Between Surface Resistance and Surface Resistivity